2024/06/01

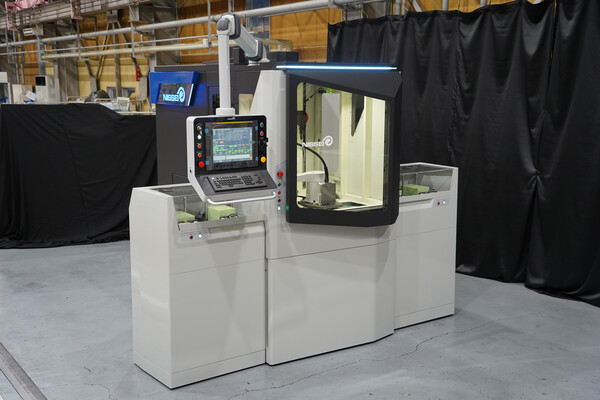

VP3-400RW

Vertical Double Disc Surface Grinding Machine for Inserts

Offers faster cycle time with updated functions and exterior design.

Main Specifications

| Machine Dimensions | 3,200 (D) x 2,900 (W) x 2,600 (H) mm φ400mm Diamond Wheels |

|---|---|

| Machine Weight | Approx. 6,000 kg |

| GW Drive Motor | AC spindle motor 15kw x 2 |

| Grinding Method | GW infeed + Linear oscillation |

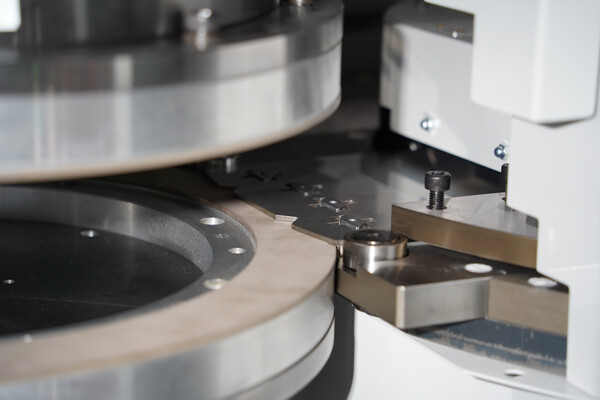

| Typical Workpiece | Carbide, cermet, ceramic inserts |

| Acceptable Workpiece Dimensions | Maximum radius of circumscribed circle: 32mm |

| Remarks | Following optional devices are available: ・Pallet stocker device utilized for your existing pallets ・Automatic loading / unloading device with SCARA robot ・Post-process gauging device ・Workpiece recipe function for Max. 300 workpiece models |

- NISSEI's unique and original high-rigid mechanism against grinding force and heat deformation achieves high-speed grinding and superior stability of thickness control.

- 180-degree-indexable carrier with two stations enables loading/unloading workpieces during grinding cycle and does not affect cycle time. Full automatic transfer system with SCARA robot (optional) achieves 4 seconds per piece of cycle time.

- As an option, it is possible to design pallet stocker utilized for your existing pallets.

- Post-process gauging device (optional) provides feedback for grinding wheel wear, which enables compensation for GW position and full automatic operation.

- 180-degree-indexable carrier with two stations enables loading/unloading workpieces during grinding cycle and does not affect cycle time. Full automatic transfer system with SCARA robot (optional) achieves 4 seconds per piece of cycle time.

- As an option, it is possible to design pallet stocker utilized for your existing pallets.

- Post-process gauging device (optional) provides feedback for grinding wheel wear, which enables compensation for GW position and full automatic operation.

- AC spindle motors are installed for main spindle drive. Thanks to rotation control of main spindles in a moment, it is possible to select: 1. two-sided simultaneous grinding mode, 2. two-sided separate grinding mode, 3. One-sided grinding mode.

- Full automatic dressing device is installed as standard. With rotary truing disks, surfaces of both diamond wheels can be simultaneously dressed.

- FANUC CNC is adopted for machine control. By workpiece recipe function, grinding and transfer parameters of max. 300 workpiece models can be stored and recalled (optional).

- Full automatic dressing device is installed as standard. With rotary truing disks, surfaces of both diamond wheels can be simultaneously dressed.

- FANUC CNC is adopted for machine control. By workpiece recipe function, grinding and transfer parameters of max. 300 workpiece models can be stored and recalled (optional).